8 tips on how to go green in the home decoration and home textiles sector

Environmental sustainability is becoming a key requirement in the European market for home decoration and home textiles (HDHT). Consumers, businesses and governments increasingly demand environmentally friendly (‘green’) practices throughout the value chain. To stay competitive in this market, you must do what you can to become greener.

Contents of this page

- Sustainability is becoming a must - be ready

- Focus on the stages in your product lifecycle that you can control

- Explore your options for material innovations

- Manage the risks in your green innovation process

- Prepare for new and updated European green legislation

- Use voluntary standards and certifications to prove your green performance

- Specify your green principles in your Code of Conduct

- Look for funding, investors and partners that can help you become greener

1. Sustainability is becoming a must - be ready

Sustainability is quickly becoming part of core consumer needs, also in HDHT. The majority (>65%) of consumers in Europe’s leading HDHT markets believe that leading a sustainable lifestyle is important. For example, most British adults prefer their HDHT products to be made sustainably and are willing to pay a bit more for this. Especially younger generations care about sustainability, and they express this by buying products that contribute to a better world. To appeal to the European market, now and in the future, you need to be sustainable.

Being green plays an important role in this, although true sustainability is a combination of:

- People: social aspects;

- Planet: environmental aspects;

- Profit: aspects like affordability, marketability, productivity and up-scalability of your sustainable offer.

European legislation is also moving towards increased sustainability, making it a must rather than an option. You need to be ready for this. With the European Green Deal, the European Union (EU) strives to become climate-neutral by 2050. New and updated legislation that makes sustainability a requirement is currently being rolled out.

The main environmental sustainability issues in HDHT are related to mass production using non-sustainable raw materials. Overproduction can also lead to surpluses in the market. Another key issue relates to low-quality products, which consumers (have to) replace quickly. The Green Deal includes a Circular Economy Action Plan, which offers a greener alternative to unsustainable production. In a circular economy, waste is eliminated via repair, reuse and recycling.

Figure 1: European Parliament – Repair, reuse and recycle!

Source: European Parliament @ YouTube

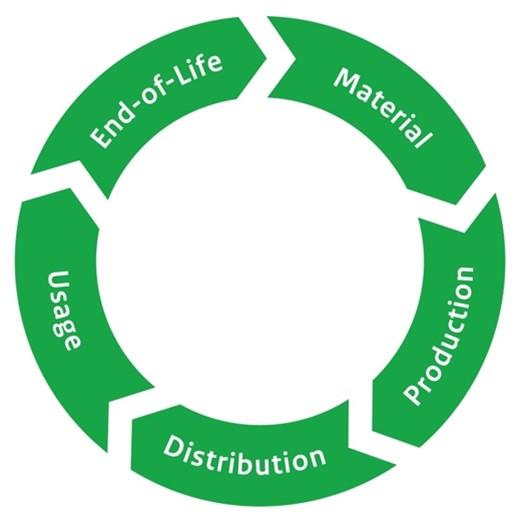

A typical product lifecycle consists of 5 aspects or stages. In a circular economy, a product’s end of life starts a new cycle. Waste no longer ends up in landfills, but can be regenerated into a new material, starting a new lifecycle. However, you can introduce (more) environmentally friendly practices in each of the 5 stages.

Figure 2: 5 stages of a circular product lifecycle

Source: CBI sustainable design training material

Examples of environmentally friendly practices per stage of the product lifecycle include:

- Material: using materials that are renewable, local, recycled/recyclable, and/or waste- or by-products;

- Production: avoiding pollution, producing energy efficiently, recycling waste, using renewable energy such as solar power;

- Distribution: reducing transport, packing products efficiently and with sustainable materials, designing your products to save space during transport;

- Usage: designing products to be durable, timeless, and/or multi-purpose;

- End-of-life: using biodegradable materials, designing products to be easily taken apart, offering take-back policies.

Tips:

- Be proactive and make your company and products greener to stay relevant in the European market;

- Combine environmental (planet) and social (people) aspects. When introducing new sustainable practices, be sure that they make sense business-wise (profit);

- Be specific when communicating the sustainable aspects of your products or company. Consumers may prefer different elements of sustainability for different product categories, so generic statements may not convince them;

- For more information on the social issues of sustainability, see our tips on how to become socially responsible.

2. Focus on the stages in your product lifecycle that you can control

Becoming a more environmentally friendly company is a process. Every product has the potential to become greener. You just have to take it step by step and focus on the aspects you have the most control over.

A common way to compare environmental impacts is via estimated carbon footprints (in kg CO2 equivalent emissions). In HDHT, this can be challenging due to long value chains and different production methods. Although large and heavy products generally have relatively large carbon footprints, emissions can vary widely within product groups. Estimations from different sources cannot be compared due to different methodologies and definitions. Instead, you can compare the carbon impacts of producing materials as estimated by the European Environmental Bureau.

Table 1: Carbon impacts of producing materials contained in furniture

| Material | Textiles | Aluminium | Plastic | Steel | Chipboard | Wood |

|---|---|---|---|---|---|---|

| Tonnes CO2 equivalent per tonne of material | 22.0 | 10.0 | 3.0 | 2.5 | 0.7 | 0.1 |

Source: European Environmental Bureau (2017)

While you may be able to use wood instead of plastic, these materials are not all interchangeable. You often have to make sustainable choices within a particular category, such as textiles. In general, synthetic (textile) fibres show a higher impact on climate change than natural fibres. For example, the European Commission’s Joint Research Centre (2014) has estimated the impact of silk at 14.9 kg CO2 eq. per kg of fabric, compared to 35.7 kg for acrylic.

However, choosing environmentally friendly raw materials is not the only way to improve your environmental impact. You can lower your product’s carbon footprint in each of the 5 stages of your product’s lifecycle. As a producer, you have the most control over environmentally friendly practices in stages 1-3: material, production and distribution. While these should be your first focus, you can also work on stage 4 (usage) and 5 (end-of-life) by collaborating with your European partners.

While distribution adds to a product’s carbon footprint, smart choices in terms of materials and production methods can help reduce the overall emission. In this context, European importer/wholesaler originalhome has demonstrated that European sourcing does not always have the smallest carbon footprint. Because their glass from Zanzibar (Tanzania) is upcycled and processed by hand, it emits even less CO2 than new glass produced in Germany, despite being imported by sea. This illustrates the importance of the green efforts you make in your choice of materials and production methods.

Artisan House from Bangladesh uses natural materials from renewable sources, such as seagrass, jute, straw, date and palm leaf, and water hyacinth. Most production is done by hand by skilled artisans, or with the help of simple machinery. The company actively tries to improve its environmental performance. The latest addition to the company’s facilities is an effluent treatment plant, which cleans the water used in production so it can be reused or released into the environment.

To estimate the environmental impact of a product across its lifecycle, you have to do a life cycle assessment (LCA). For example, Eco Impact has developed a methodology specifically for the HDHT industry. Impact ratings per product are becoming increasingly popular. Norwegian furniture manufacturer Vestre started sharing EPDs (Environmental Product Declarations) in 2020. This practice is also catching on in lower-end segments. Since 2022, Dutch retailer Xenos publishes Nature Impact Ratings based on the Global Sustainable Enterprise System (GSES).

Tips:

- Focus first on developing improved environmental practices in product lifecycle stages 1-3;

- Collaborate with your European partners on sustainable practices in the remaining aspects of the lifecycle – for instance, by co-designing for durability or modularity or developing sustainable materials together;

- Use a self-assessment tool to estimate the environmental impact of your products, such as the 2030 Calculator.

3. Explore your options for material innovations

Green innovation can take place across your product lifecycle, but it must meet market preferences. Sustainability is now a core driver for European buyers. They can be motivated by personal reasons, wishing to contribute to a better world for future generations. In addition, new EU legal requirements make sustainable business a must.

Buyers may also be motivated by the competitive advantage offered by new sustainable concepts. Currently, they are particularly interested in material innovations. New concepts can create interest at trade fairs and on social media. It helps if these innovations are visible in the product, for instance through attractive texture, colour or other surface features. Certification also helps, as well as communication using videos and other types of storytelling.

There are 3 kinds of material innovations:

- Recycling post-industrial or pre-/post-consumer waste: well-established practices such as re-using off-cuts from the garment industry in home textiles, or ocean plastics in furniture or curtains;

- Engineering ‘from the lab’: especially big industry, using technology or chemical processes to create, for example, new and cleaner dyes or non-pollutive and cruelty-free faux leather;

- Applying agricultural by-products or excess harvest: possibly the latest in material innovations in HDHT, including creating new textiles from pineapple leaf fibres or tree bark.

Figure 3: CBI webinar on sustainable innovations for your HDHT business

As with any sustainable innovation in your company or value chain, developing sustainable materials into attractive products is a process. When you start to prototype a sustainable innovation with your chain partner, you will often be asked to make changes to the composition of the material, to the cost and price, or to the design properties. Innovation consists of trial and error, and overnight success is rare.

Ugandan manufacturer Easy Afric Designs has successfully developed a barkcloth material from the Mutuba tree, a fig species. A felt cloth is produced by matting the bark that is sustainably harvested by hand, using simple man-made tools. This technology is recognised as UNESCO Intangible Heritage. The barkcloth is used for home textile products such as cushion covers and fashion accessories. The company has managed to upscale production sufficiently to offer it as a material or end-product that has already been exported worldwide.

Tips:

- See what you can do in any of the 3 kinds of material innovation. Your choice depends on whether you can access consumer or industrial waste to use for an innovation process. If you are in an agricultural setting, the easiest choice might be to use agricultural waste;

- Do not go it alone – form partnerships. Innovation costs time and money. You can share this investment by partnering with a manufacturer whose core business is material innovation. These companies are familiar with the trial and error of the process, and they can dedicate sufficient resources. Partners can also help you with formal verification, cooperate with you on design, and boost the communication of your innovation;

- Have your documentation in order. This is key to facilitating formal verification towards the market and your buyer later on. Work with a bill of materials and spec sheet, and add any internal and external test reports to the relevant files. Also include any material, product or process certifications you may have. European buyers are facing increased legal requirements related to transparency and chain of custody, so the more complete your administration system, the more attractive your offer;

- Communicate with your partners in the supply chain. Innovation processes need intensive communication across the value chain to keep partners informed and motivated. This also applies to potential problems: the more you share and tackle challenges with your partners, the more they feel empowered and motivated to move forward. Keeping quiet is always the worst option;

- Whether you are offering a sustainable product or process innovation, help your buyer create visibility in the market via storytelling and/or certification.

4. Manage the risks in your green innovation process

When you are working on the green innovation of your product or process, risks and challenges can come in different forms. In HDHT, most relate to:

- Money;

- Time;

- Verification;

- Design.

Money

Investment should be manageable and in line with an expected return. For instance, green product innovation often involves lots of groundwork with the artisans or manufacturers, negotiations with suppliers, test rounds, and retries. Such development costs cannot simply be included in the cost price of your product. They should come from a special research and development (R&D) budget or external investment.

Cost estimates at the prototyping stage may differ considerably from those in later stages, when production systems have been adapted. When developing more sustainable products or materials or investing in certification, however, your buyer needs an estimated price at an early stage to assess whether it will work for their market. This makes budgeting key to a successful innovation approach, despite how difficult this may be.

Process innovations carry a similar risk. For example, introducing a new kiln in your ceramics business may affect the type and use of material, how people work, your energy source, and the quality and volume of your output. All of this has a direct link to cost-effectiveness.

Time

If the green innovation process takes too long, your partners further across the value chain may lose faith or interest. Suppliers of raw materials or semi-products may become impatient to get orders for this innovation. Your buyers may need such innovation for competitive reasons, especially if they have invested in the innovation process. They may also have started internal and external communication about it. To manage expectations, you need to keep your partners involved and updated.

Verification

You need to make the green innovation of your product or process transparent and verify the environmental values of your innovation. This requires an admin system that includes:

- A bill of materials;

- Documentation on all internal and external testing of your product or production system;

- Any certifications of raw materials or machinery, either from your suppliers or ordered by you from specialised certifiers or labels.

If you cannot provide verification, your innovation may not convince buyers or help them meet EU legal requirements.

Design

Your green innovation needs to meet market requirements in terms of look, feel and design flexibility. If it does not, buyers may turn to other options. If you redesign your process to become greener (such as lower energy use), make sure this translates into a more favourable price offer for your buyer as well.

Tips:

- Communicate consistently and effectively throughout the innovation process to ensure commitment from all partners in the value chain, from suppliers to buyers. If you do not, everyone involved may lose time and money;

- Ensure that your sustainable innovations ‘fit’ your production system. If your material innovation requires different production techniques, your artisans or workers may resist or require training. If you adapt part of your production system, for instance by replacing a kiln, make sure that it fits neatly in the production process – before (clay processing, glazing), during (type of energy used, firing time) and after it (waste percentages, surface effects);

- Try to combine environmental benefits with social benefits in your innovations and communicate both benefits to your stakeholders. If you reduce pollution by changing your energy source (from coal to gas, or gas to solar), see if that also leads to improved working conditions (health and safety benefits).

5. Prepare for new and updated European green legislation

Sustainability is becoming a must in the European market. Not only because buyers and consumers are asking for it, but also because of new legal requirements. The European Green Deal includes both environmental and social requirements. Its Circular Economy Action Plan includes initiatives along the entire product lifecycle. It targets how products are designed, promotes circular economy processes, encourages sustainable consumption, and aims to prevent waste. For example, by introducing new legislation on sustainable design and packaging.

Within this context, many European laws are currently being revised, and new laws are being developed. Many of these laws apply to European companies’ entire value chains. This means that for your buyer to comply, you must meet the requirements of this legislation as well. So be prepared.

Corporate Sustainability Due Diligence Directive

The Green Deal’s new Corporate Sustainability Due Diligence Directive (CSDDD – EU 2024/1760) requires larger companies to identify and – where necessary – prevent, end or reduce negative impacts of their activities on human rights and the environment. Both in the company’s own operations and in its value chains.

As a small or medium-sized enterprise (SME) from a developing country, your company is not within the scope of the CSDDD. However, your European buyers may be. This means that even if the new rules do not apply to you directly, they may apply indirectly via your buyers. Larger buyers will have to perform the required due diligence on their direct business partners, which may include you, as a supplier. The European Commission plans to publish guidelines to help companies conduct due diligence. Some countries have already introduced national due diligence legislation, like Germany.

The CSDDD entered into force on 25 July 2024. The rules are set to apply according to a staggered approach, with the first group of companies starting on 26 July 2028 and full application being on 26 July 2029. However, the European Commission has proposed an Omnibus package to simplify due diligence requirements for sustainability. The proposal aims to protect SMEs with a new voluntary standard for SMEs (VSME), limiting the number of requests for general sustainability information from larger companies.

Ecodesign for Sustainable Products Regulation

The new Ecodesign for Sustainable Products Regulation (ESPR – EU 2024/1781) entered into force in July 2024. This new law aims to ensure that products:

- Are designed to last longer;

- Are easier to reuse, repair and recycle;

- Incorporate recycled raw materials wherever possible.

It also restricts single use, tackles the (too) early failure of products, and bans the destruction of unsold durable goods. The regulation also introduces Digital Product Passports with information about the environmental sustainability of products, like durability and recycled content.

The rollout of the ESPR involves the publication of working plans, which set out the products and measures to be addressed. According to the first working plan, the measures for textiles are due in 2027, and those for furniture are due in 2028. The measures would typically be applicable 18 months later.

Strategy for Sustainable and Circular Textiles

In 2022, the European Commission presented a proposal for a Strategy for Sustainable and Circular Textiles as part of the Green Deal.

The goal of this strategy is to ensure that by 2030, textile products placed on the European market are:

- Durable, repairable and recyclable;

- Made of recycled fibres, to a large extent;

- Free of hazardous substances;

- Produced respecting social rights.

Deforestation Regulation

The new Deforestation Regulation (EUDR – EU 2023/1115) is set to replace the current EU Timber Regulation (EUTR), which bans illegally harvested timber products from the EU market. The new EUDR applies to various forest-based products (Annex I), including wooden furniture. It ensures that no deforestation or forest degradation has taken place along the value chain, as it requires tracing wooden products back to the plot of land where they were produced. Like the EUTR, the new EUDR should recognise FLEGT-licensed products.

To be allowed onto the European market, covered products must be:

- Deforestation-free (from land that has not been subject to deforestation or forest degradation after 31 December 2020);

- Produced in accordance with the laws of the country of production;

- Covered by a due-diligence statement.

The EUDR came into force in June 2023, but its application has been postponed. It will now apply from 30 December 2025 for large and medium-sized enterprises, and from 30 June 2026 for micro and small enterprises. For timber products produced before 29 June 2023, the EUTR will continue to apply until 31 December 2027. The EUDR factsheet for SMEs provides information for SMEs that place relevant products on the EU market.

Plastics Strategy

The EU’s Plastics Strategy is transforming the way plastic products are designed, used, produced and recycled in the EU. The Single-Use Plastics Directive (EU 2019/204) bans selected single-use plastic products for which alternatives exist on the market. It includes products like single-use plastic cutlery and plates. Replacements must be made from biologically sourced materials that can be composted. The Plastics Strategy also includes the Plastic Bags Directive (EU 2015/720), which aims to significantly reduce the consumption of lightweight plastic carrier bags.

Packaging

The Packaging and Packaging Waste Directive (PPWD – 94/62/EC) aims to prevent or reduce the impact of packaging and packaging waste on the environment. Buyers may therefore ask you to minimise the use of packaging and/or to use sustainable (recycled) materials.

The new Packaging and Packaging Waste Regulation (PPWR – 2025/40) entered into force on 11 February 2025. This regulation will apply from 12 August 2026, replacing the PPWD. As a regulation, the PPWR ensures that the same rules apply across the EU. It aims to prevent packaging waste, minimise substances of concern and ensure that all packaging on the EU market will be recyclable in an economically viable way by 2030. It also strives to safely increase the use of recycled plastics in packaging.

Green claims

In 2023, the European Commission proposed a new Green Claims Directive. A green claim is a claim that a company makes about the environmental aspects or performance of its products and organisation. The proposal aims to:

- Make green claims reliable, comparable and verifiable across the EU;

- Protect consumers from ‘greenwashing’ (companies pretending to be more sustainable than they are);

- Contribute to creating a circular and green EU economy by enabling consumers to make informed purchasing decisions;

- Help establish a level playing field when it comes to the environmental performance of products.

Figure 4: EU measures to tackle greenwashing

Source: European Commission @ YouTube

The proposal is currently pending. If/when the Directive is approved, any (voluntary) green claims you or your buyer make about your product would have to follow minimum requirements for substantiating, communicating and verifying environmental claims. Until then, the Unfair Commercial Practices Directive (2005/29/EC) and the new Directive to empower consumers for the green transition (EU 2024/825, which will apply from 27 September 2026) already ban misleading and false environmental (‘green’) claims.

Tips:

- Prepare for new European legislation. Discuss with your buyers what they need from you (such as documentation or certification) and how you can help each other in the process;

- Read more about the CSDDD, the ESPR and the EUDR;

- Stay up to date on the implementation of the ESPR and EUDR, as well as on the proposed rollout of the Green Claims Directive;

- For more information about (new) legislation, see our studies on buyer requirements for HDHT and how the EU Green Deal will impact your business.

6. Use voluntary standards and certifications to prove your green performance

Voluntary sustainability standards and certifications can 'prove' your sustainability and may help you to facilitate your buyers’ due diligence processes.

The ISO 14001 standard sets the criteria for an effective environmental management system. Such a system can help companies reduce their environmental impact and comply with regulations. You can use this standard as a guideline or apply for certification. ISO 14001 certification clearly demonstrates your commitment to running a green business.

Figure 5: ISO 14001

Source: ISO @ YouTube

In addition to documenting your company’s environmental performance as a whole, you can also opt for material-specific certification. You can either apply for certification of your own materials or buy certified raw materials from your suppliers.

Popular sustainability certifications include:

- Wood, paper or other forest-based materials: FSC and PEFC chain of custody certification;

- Recycled wood or paper: FSC Recycled label;

- Textiles: GOTS (organic) and OEKO-TEX Standard 100, STeP and/or Made in Green;

- Recycled materials: GRS and RCS;

- Specific products: EU Ecolabel and the Nordic Swan Ecolabel.

These environmental standards often include social requirements too. In turn, popular sustainability initiatives such as BSCI and Sedex (with its SMETA audit) that mainly focus on social standards also contain environmental components. Even fair-trade labels like the World Fair Trade Organisation (WFTO) Guaranteed System and Fair For Life certification include aspects of environmental sustainability. This illustrates the importance of a holistic approach to sustainability, including both green and social efforts.

Ashoka Exports is over half a century old, but it is still up to date with today’s market requirements for verification and traceability. The Indian company offers various types of bags and home textiles in jute and cotton. Their "constant endeavour" is "to move towards a greener globe", starting with their own product and process. Ashoka’s organic cotton is GOTS-certified. They also have GRS certification, showing their belief in the recycling process. They also consider social aspects, being audited according to the SMETA social standard.

Tips:

- Determine which initiative or certification programme would be the best fit for you and apply for it if you can. Even if you cannot apply, you should carefully document your company’s processes to support your story;

- For wood or other forest-based materials, see the 6 steps towards FSC chain-of-custody certification and/or 6 steps towards becoming PEFC Certified. For textiles, consider the possibility of sourcing certified organic cotton yarn or fabric instead of applying for your own certification;

- Read more about FSC, PEFC, GOTS and OEKO-TEX in the ITC Standards Map;

- Use self-assessments like the BSCI Producer Self-Assessment, a Code of Conduct like the ETI Base Code of labour practice, or WFTO’s 10 Principles of Fair Trade to show your overall sustainability performance;

- For more information about sustainability standards and certifications, see our study on buyer requirements.

7. Specify your green principles in your Code of Conduct

A Code of Conduct is a set of values and principles that a company and its employees must adhere to. It clearly communicates these rules to both internal and external stakeholders. A good Code of Conduct inspires the people inside your organisation and makes external partners want to engage with you more.

Codes of Conduct are a process. They make corporate promises to the world. Stakeholders will base their belief in your promises on how they have experienced your company’s behaviour and how it matches the Code of Conduct. So, you should start your strategic process with a mission statement and a few years of living this statement, to establish trust. Then, you can develop a Code of Conduct.

A well-rounded Code of Conduct contains both green and social practices. If you are mainly environmentally oriented, you start with detailed and ambitious green promises. This is how your stakeholders know you and appreciate you. If your concept has been built on a particular social principle – like women empowerment – then it makes sense to start there. You should be authentic and use your tone of voice in your Code of Conduct. Do not use complicated words if they are not yours. Make sure your stakeholders can understand and ‘believe’ you. Copy-paste documents will not convince them.

You can, however, use internationally known and accepted Codes such as the BSCI Code of Conduct as a starting point. BSCI members often base their supplier Code on this format, like Danish retail chain Søstrene’s Grene. The BSCI Code of Conduct mainly focuses on social principles but also includes a paragraph on protecting the environment. These Codes of Conduct are quite generic because they apply to different types of companies in different sectors. Your company’s Code should be more specific and tailored to your values and practices.

Tips:

- Be specific about what you are doing. Your Code of Conduct describes your specific practices, so avoid copying others. Authenticity in communication is key and that includes your Code, both in its content and tone of voice;

- Describe what you still intend to improve, how and when. Sustainable innovations are never perfect. Being honest about this and your ambitions will improve the credibility of your statements.

8. Look for funding, investors and partners that can help you become greener

To make your business greener, you may need support – be it financial or practical. Partnerships are often your best option.

Other forms of indirect support to facilitate your sustainable innovations are also possible. For example, co-creation with partners in your part of the chain (such as suppliers and processors of raw materials) can be a way of sharing costs and know-how. It also keeps the time-to-market as short as possible.

For indirect investment, organisations like PUM, SES and SEC may be able to support you with expertise and sometimes even with small budgets. This support may speed up your innovation process, cut costs and create market acceptance. Especially when the assistance is provided through development programmes such as those by CBI, GIZ or ITC.

Another option is crowdfunding, which is quite common for sustainable innovations today. However, this requires a lot of preparation, communication and actual fundraising for relatively limited funds. Crowdfunding initiatives are often aimed at Western businesses, in which case you may need to partner with your buyer. Examples of platforms are GoFundMe and Indiegogo.

In the European fairtrade segment, some investment from importers and world shops is available periodically for sustainable innovation. Fairtrade importers and retailers may have funding available to support the small and medium-sized enterprises (SMEs) that supply them. They often reserve part of their profit for investment in SME projects.

Tips:

- Form partnerships with your European buyers to formulate a (business) plan around your sustainable innovations. This can help them to access EU or private funds related to sustainable innovation. Such partnerships will also create a stronger, lasting relationship with your buyer;

- Discuss with your buyers if they want to contribute financially or with know-how in exchange for the opportunity to introduce your sustainable innovation exclusively in their market channels;

- Use financial professionals to help you formulate proposals and write a business plan if you want to access external funding. They may of course charge a fee.

Globally Cool carried out this study in partnership with Remco Kemper and GO! GoodOpportunity on behalf of CBI.

Please review our market information disclaimer.

Search

Enter search terms to find market research