8 tips on how to use AI in the apparel industry

In the apparel industry, artificial intelligence (AI) is applied in various areas: from product design and collection development to sewing and quality control. This results in higher product quality, improved efficiency and reduced environmental impact. In 2023, McKinsey consultancy predicted that generative AI could boost the global fashion industry’s profits by up to $275 billion in five years. This report explains how you too can use AI to your benefit.

Contents of this page

- Use AI to develop and design new products

- Use AI to improve the manufacturing process

- Improve your supply chain management with AI

- Train workers with the help of AI

- Use AI to promote sustainability

- Improve your customer relations and marketing with the help of AI

- Know the challenges of using AI

- Stay updated on the future prospects of AI in apparel manufacturing

1. Use AI to develop and design new products

Artificial intelligence (AI) tools can create new content such as text, images, music or code by learning patterns from existing data. This way it can simulate human-like creativity and output. The main benefit is that you can use AI to automate complex tasks, boost productivity and enable rapid innovation. AI can be especially useful in apparel design and development, as it is good at generating images and 3D models.

The traditional way of designing apparel, based on the craft and creativity of the designer, is being radically transformed. AI allows for the creation and quick sharing of realistic 3D clothing models that simulate draping, movement, textures and colours. This has reduced the need for physical samples and has sped up the approval process. Now, based on its analysis of large amounts of data, AI helps to accurately predict consumer trends. It can subsequently generate highly detailed designs based on a sketch, an image, or even just a text prompt.

Trend forecasting

Traditional fashion supply chains are built on seasonal collections and outsourced production. The entire process from design to retail can take up to 12 months. The risk of a long time period between designing garments and selling them is obvious, as companies could suffer from mismatches between supply and demand – they either order too much or too little, or the wrong style, colour or shape. This is the reason that trend forecasting became its own industry, with consultancies like WSGN offering trend intelligence.

Traditionally, trends would flow from the runways to the general public via magazines and TV. Following fashion shows and media outlets and going spy shopping were the tools everyone had to predict trends. Big data analysis and AI have changed all this. Consultancies like Edited started analysing large amounts of textual metadata from apparel items on online retail platforms to track trends in the offering of garments. This results in a superior form of spy shopping by analysing trends in styles, prices, colours and product descriptions.

With the help of AI, consultancies like Heuritech, Livetrend and Stylumia are no longer limited to analysing only textual data. Their AI models track large amounts of images from various online sources, including social media accounts, to analyse which types of garments are worn, how consumers combine them and how they are perceived by online fans. By analysing trends in past data, AI can make accurate predictions about the future popularity of any style, in any colour, shape or form, among any target group in any country.

While Edited, Heuritech, Livetrend and other consultancies mentioned here offer mostly paid AI services, they provide free information on their blog pages.

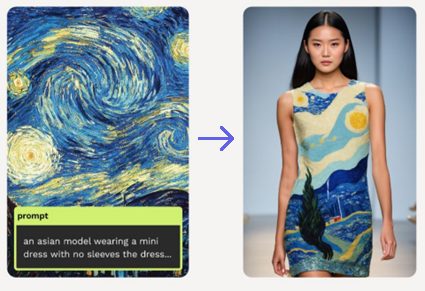

Figure 1: Based on an image and a text prompt, refabric’s AI model can generate a photorealistic design, including patterns and a tech pack

Source: refabric.com

Automated design tools

Tools for 3D designing and prototyping such as CLO, Lectra, Alvanon or Browzwear use AI to automate adjustments and predict fit for their realistic 3D clothing models. These simulate the draping, movement and texture of various fabrics and materials. This reduces the need for physical samples, allowing designers to verify patterns and visualise how a garment will look and behave on different body types. This process speeds up the approval process while reducing material waste (paper, muslin and fabric), saving time and money.

The starting point for the creation of a 3D digital prototype can be a sketch, an image or even a simple text prompt. French start-up company refabric offers an online platform requiring few technical skills that allows designers to generate a new design in seconds, based on images or text. It even automatically generates patterns and a tech pack. Lectra-partner Six Atomic also generates 3D designs and sends the patterns straight to the factory, speeding up approval and eliminating mistakes and thus waste.

Grading (scaling a base pattern up or down to create different sizes, e.g. S, M, L, XL) is another process made easier and more accurate by AI. In the past, grading was done manually, which was time-consuming and prone to mistakes. Now, software like Lectra or CLO 3D grades patterns automatically with great accuracy. The software uses algorithms to apply pre-defined rules for each size range, ensuring consistent fit across all sizes.

Figure 2 shows how AI-powered software can generate digital 3D models that simulate the draping, movement and texture of various fabrics and materials.

Figure 2: AI-generated model on the left vs the manufactured sample on the right

Source: CLO3D.com

Customisation and personalisation

AI also enables the creation of on-demand, highly personalised apparel items, which can be made in small factories close to the market. This can turn offshore production with long lead times obsolete. AI-powered virtual fitting rooms such as Vue and My Fitting Room allow consumers to see how clothes will fit on their body digitally, reducing return rates. After generating a 3D model and patterns, AI can automatically assign production tasks to the most suitable machines or lines, optimising efficiency for small-batch production.

Tips:

- Some AI tools are inexpensive or even free/freemium – e.g. Mistral, ChatGPT, CoPilot, Gemin, Claude – while others require a more serious investment. When selecting for paid services, always evaluate where AI can deliver the most impact. This may include design, pattern-making, manufacturing, quality control or inventory management;

- Stay up to date on innovations and techniques by following Innovation in Textiles or Sourcing Journal;

- Read the CBI study ‘9 tips to go digital in the apparel sector’ for more information on digitalisation and automation in the apparel industry.

2. Use AI to improve the manufacturing process

AI can help you enhance the manufacturing process in an apparel factory by improving efficiency, enhancing quality control, reducing waste, enabling automation and optimising production workflows. Factories that integrate AI into their processes can stay competitive in the fast-evolving fashion industry.

Smart fabric-cutting and -sewing machines

AI is not only transforming pattern-making in apparel factories, but also fabric cutting by improving precision, speed, material utilisation and automation. AI-driven Computer Aided Design (CAD) software like Gemini and Tukatech can optimise fabric-cutting layouts and detect errors in pattern symmetry and seam alignment. AI-powered cutting machines can make adjustments to the cutting path based on roll length or defects in real time and will adjust the blade movement based on fabric thickness, elasticity and texture.

Even the sewing process is increasingly automated with the use of AI. However, this step in apparel production is still very much dependent on human action. Supplier of fully automated sewing robots SoftWear Automation wants to create a fully on-demand supply chain with the help of AI, enabling super-efficient localised production. Sewing machines by companies like Juki and Brother use smart sensors and AI to adjust stitch length, tension and speed based on fabric type and complexity. The newest AI-powered sewing machines can even detect potential stitching issues in real time and self-correct.

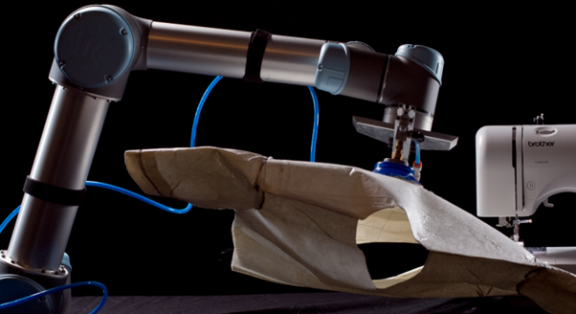

Start-up company Sewbo goes even further, by promising to assemble entire garments by machine. AI-controlled robotic arms manipulate temporarily stiffened fabrics and operate the sewing machines to create an apparel item. The fabric panels can be easily moulded and welded before being permanently sewn together. The reusable fabric stiffener can be removed with a simple rinse in hot water at the end of the manufacturing process, resulting in a soft, fully assembled piece of clothing.

Figure 3: Sewbo offers AI-powered robotic arms that can assemble entire pieces of apparel

Source: Sewbo.com

Quality control

Quality control and inspection are critical in apparel manufacturing to ensure that defective materials do not move forward in production. AI-driven quality control can detect defects more quickly and accurately than humans, improving efficiency and reducing mistakes. With AI, smart manufacturing enables predictive maintenance, minimising downtime and boosting productivity. This technology allows companies to analyse data for consistent and precise quality control, reducing waste and providing a competitive advantage.

Predictive maintenance of machinery

AI algorithms can predict when machines need maintenance by analysing sensor and historical data, enabling factory owners to schedule maintenance proactively. This prevents failures and reduces downtime, improving operational efficiency. It also maximises equipment life, saving costs for maintenance and replacement. A study by Deloitte revealed that predictive maintenance can reduce maintenance costs by 20–30% and increase equipment uptime by 10–20%.

3. Improve your supply chain management with AI

Supply chain management, resource management and energy efficiency are crucial processes for apparel manufacturers. By analysing historical data, market trends and external factors such as weather conditions, AI can predict demand, optimise stock levels and streamline production schedules. This reduces excess inventory, prevents waste and wasteful processes, and increases speed to market, saving time and money.

Demand forecasting

AI can enhance apparel demand forecasting by analysing sales data (both historical and real time), weather patterns, local events and seasonal trends. Tools such as Forecast Pro and Blue Yonder use AI to predict future demand, adjusting for factors like temperature shifts, holidays and promotions. This enables manufacturers and retailers to optimise inventory levels, reduce overstock or stockouts, and ensure products are available when needed.

Inventory optimisation

Good inventory management is crucial for running a successful apparel factory. Having the right materials in stock – not too many, not too few – at the right time means you can run an efficient business. Tools like Apparel Magic and o9 Solutions use AI to enhance merchandising by providing advanced analytics and demand-planning capabilities. They help apparel manufacturers optimise product assortments, manage inventories and adapt to changing market conditions while reducing costs and improving profitability.

Tips:

- Read how fast-fashion retailers like H&M and Zara optimise their supply chains and manage inventory more effectively by using AI;

- Desigual, a Spanish fashion retailer, has recently used AI to launch new on-demand collections. Another Spanish company, Mango, generated an ad campaign using AI to create digital avatars;

- Check Sewbo’s demonstration video of a fully automated apparel-making process on Vimeo.

4. Train workers with the help of AI

High employee performance is crucial for running an efficient and successful apparel factory. AI can help you train your employees better by providing personalised, interactive and efficient learning experiences.

Scheduling and task allocation

Planning well is crucial for running an efficient and successful apparel factory. AI-powered tools like FastReactPlan, SAP and Blue Yonder can help with this by prioritising tasks based on urgency and allocating resources. They can also balance workload by analysing workers’ skills, experience and performance, and automatically assign the right tasks to the right individuals. This helps avoid bottlenecks, reduce worker fatigue and ensure smooth workflow. Plus, they can help prepare you for busy periods in advance.

Training simulations and skill assessment

If you want to guarantee that your employees have the right skills to perform tasks successfully, invest in an in-house training programme. AI tools such as Axonify or Disco can help analyse workers’ performance by processing data from sewing line sensors, ERP systems, time tracking and quality control reports. These tools can create tailored training programmes based on individual skill levels (working speed, number of actions, number of defaults) and the learning pace of your employees. This ensures that the training is relevant and efficient for each individual, helping them learn new skills and increasing overall employee retention.

Moreover, AI-powered tools can provide real-time feedback during tasks, helping operators improve their techniques as they perform their job at the workstation. For example, AI systems can detect errors in stitching or cutting and offer corrective suggestions instantly. Tools such as Poka or Augmentir can help standardise tasks, develop training programmes and onboard new employees faster.

Another option is to use freemium tools like ChatGPT or Claude to help you outline an in-house training programme for new and existing employees. Based on specific questions or commands (prompts), these tools can generate step-by-step guides, safety protocols and checklists tailored to each production stage (such as cutting, stitching or quality control). They can also help translate training materials into multiple languages and simulate common production issues to create different scenarios.

Improved worker safety

AI can help you improve worker safety in your factory in several different ways. First, AI-powered CCTV analytics can help you detect unsafe behaviour, for instance not wearing PPE or operating machines improperly. Combined with wearable sensors, AI can detect fatigue or abnormal movements, preventing injuries. Furthermore, AI can help improve machine maintenance planning, preventing accidents.

Finally, AI-powered automated machines in an apparel factory can directly increase worker safety. A fully automated and closed dyeing and laundry system, for instance, lowers exposure of employees to potentially dangerous chemicals and machinery.

Tips:

- Do not underestimate how difficult it can be to implement AI-powered tools in your factory. Consider partnering with external experts, such as AI consultancies, research institutions or technology vendors;

- Before introducing AI-powered tools in your factory, set KPIs for yourself and monitor improvements. This way you will ensure that AI investments are delivering the desired results. KPIs could include metrics such as cost savings, productivity improvements or customer satisfaction scores;

- To learn more about optimising the workflow in your factory, read the CBI study ‘7 tips on how to increase efficiency in an apparel factory ’;

- Check this article by Stratpilot to learn how to write good AI text prompts to develop employee trainings programmes.

5. Use AI to promote sustainability

AI can help reduce your environmental impact and report on progress in many different ways. Generative AI can make machinery work more efficiently, saving time and resources; it can optimise material use and minimise waste by suggesting the most efficient cutting patterns for fabrics. It can even design clothes to be more durable and timeless, reducing the need for frequent replacements and promoting slow fashion.

Reduce material waste

As explained earlier, AI can help you optimise your inventory and prevent overstock. Further in the production process, AI-driven CAD software can optimise fabric-cutting layouts and detect errors in pattern symmetry and seam alignment. This greatly reduces wastage during cutting. Even during assembly, 10-15% of fabrics may end up as waste due to production errors resulting in fabric offcuts.

Optimise energy and water usage

Apparel manufacturing is an energy-intensive process, especially in factories lacking energy-saving solutions. Production steps including sewing and ironing are still done mostly manually, sometimes using outdated, energy-intensive equipment. AI can help apparel factories reduce energy and water consumption by using smart energy management systems that analyse real-time data from machinery, adjusting power usage based on demand and minimising waste.

In water-intensive processes like dyeing and finishing, AI-driven sensors can monitor water usage, identifying leaks and optimising flow rates to reduce waste.

Sustainable sourcing

AI can make it easier and more efficient to source fabrics by analysing supplier data, pricing trends and quality metrics to recommend the best options. Tools like FabricDNA, TexIntel and Pivot88 can help manufacturers identify fabrics based on quality or performance metrics and automate sourcing decisions. This reduces costs and improves supply chain reliability and transparency.

Process and automate data and reports

AI simplifies sustainability reporting in apparel factories by automating data collection, analysis and compliance-tracking. Sensors can monitor energy, water and waste levels in real time, while AI compiles this data into detailed reports. AI-powered analytics tools identify inefficiencies, suggest sustainability improvements and track progress towards goals. Platforms like Higg Index and tex.tracer streamline compliance with environmental regulations and certifications.

6. Improve your customer relations and marketing with the help of AI

AI can help you improve your relations with buyers and end users in Europe and improve your overall marketing and communication strategy. AI tools can be used, for instance, to analyse markets, smoothen communication with buyers and enhance customer experience.

Marketing and market strategies

Consultancies like Heuritech, Livetrend and Stylumia use AI to help you accurately predict trends in styles, colours, qualities and price levels for different end-user subgroups and markets. Other paid tools can also help you analyse fashion trends on social media (Pulsar), create content to engage meaningfully with people online (Braze), or create advertisements, social media and blog posts (Anyword).

Some helpful AI tools are available for free. Thryv’s online presence scanner lets you find out how your business compares to online competitors. Canva’s AI generator creates AI pictures from text prompts, while Photoroom lets you edit them. Grammarly’s AI assistant helps you correct and write engaging marketing material. For an interesting overview of free AI tools, check out this article by Thryv.

Chatbots

AI customer service chatbots like Zendesk, Freshchat and Tidio can improve buyer communication by providing instant, 24/7 support for inquiries on order status, production timelines and material sourcing. They handle routine customer service tasks, reducing response times and freeing up human staff for complex issues. AI-driven bots analyse buyer feedback, helping you improve service and product quality. They also assist in handling complaints and returns efficiently.

Translation tools

Swift and accurate communication with buyers is crucial for running a successful business. You can of course hire multilingual employees, assign translators (try Upwork or Fiverr) or translate your text with tools like Google Translate. Freemium online AI tools like Claude, Gemini, ChatGPT and Grammarly can also instantly translate and summarise text for you, improve your grammar, or write a response and read it out loud. Tools like Microsoft Teams and DeepL offer real-time voice translations during video calls.

Virtual try-ons

AI tools can generate 3D designs and prototypes that simulate the draping, movement and texture of various fabrics and materials. AI tools like Zyler and Vue.ai can also enable virtual try-ons by using computer vision and augmented reality (AR) to map clothing onto a consumer’s body. They analyse body shape, movement and lighting for a realistic fit, enhancing online shopping by improving accuracy and reducing returns.

Tip:

- Read this article on the website of apparel trade fair Premiere Vision about the applications of AI to improve sustainability.

7. Know the challenges of using AI

AI is seen as a revolution in the apparel industry, boosting efficiency, sustainability and customisation. But beware that implementing AI requires careful planning, especially for smaller factories in developing economies facing high costs, infrastructure challenges and workforce adaptation issues.

Bias, copyright infringement and inaccuracies

Be aware that AI generates content based on underlying data. If the data is incorrect or one-sided, it may create biased content. The same applies to copyright protection. AI may use legally protected content to generate new texts, images or videos that infringe on the copyrights of protected materials. Always ask any supplier of AI tools what type of data they use to train their models, and make sure your AI-generated content does not infringe on any copyrights.

Another well-known fact is that AI tools sometimes generate content or answers that seem reasonable but are factually wrong. It is important to regard AI tools as mere assistants to your work. Always check for accuracy.

Investment costs

First, the high cost of implementing AI solutions represents an obstacle for smaller manufacturers. Some tools like Claude, Gemini, DeepSeek and ChatGPT work on a ‘freemium’ basis. The basic version of these tools is available for free, while additional functionalities require payment. Many AI-powered software tools and hardware equipment mentioned in this report do not offer freemium deals – instead, they are often developed especially for the apparel industry and can be quite costly. Most tools work on a monthly or yearly subscription basis.

Be aware that after purchasing these tools you also need to account for the cost of training your staff on how to properly use the AI tools to your full advantage.

Start by familiarising yourself with freemium tools like Mistral, ChatGPT or Claude. This way you will get a basic idea of the power and possibilities of AI. Such tools are very good at generating text and images, so a good starting point is marketing and communication materials or styles and designs. If you want to explore more complex, tailored AI tools, always ask for a demonstration first and check the notice period. This way you will learn whether the tool is a potential match for your needs before you spend a lot of money.

Sustainability issues

Another important issue with AI is that this new technique is especially energy-intensive (in terms of both energy consumption and water usage for cooling servers). On the one hand, AI can help run your business more efficiently, saving resources, on the other hand, it has significant environmental impact itself. You should take this into account, especially if your factory has a sustainable profile.

Job replacement

AI is predicted to have a huge influence on industries that still rely heavily on manual labour, including the apparel sector. While AI offers benefits such as increased efficiency and innovation, it also comes with high costs, infrastructure limitations and workforce adaptation. Such challenges must be addressed to ensure that AI does not increase inequalities or lead to massive jobs losses, especially in developing economies. See, for instance, this article in The Business Standard about the possibility of AI replacing jobs in apparel.

The EU’s AI Act

Several European regulations limit the use of AI, including the EU’s Artificial Intelligence (AI) Act, the General Data Protection Regulation (GDPR) and the Digital Services Act. The AI Act introduces a regulatory framework to ensure AI systems within the EU are safe and respect fundamental rights. Prohibited practices include manipulative AI and emotion recognition at workplaces. When supplying to European buyers and applying AI in your factory and overall operations, try to align with European regulatory requirements.

The EU’s Artificial Intelligence (AI) Act is part of a larger set of policy measures that also includes the AI Innovation Package, the launch of AI Factories and the Coordinated Plan on AI.

8. Stay updated on the future prospects of AI in apparel manufacturing

The AI revolution is still young, but evolving fast. ChatGPT reached 100 million users within just two months after its launch in 2022. According to Gartner, thanks to AI, global investments in IT will reach $5.74 trillion, up 9.3% from 2024. As AI algorithms become more sophisticated, they will be able to tackle more complex tasks and provide even greater efficiencies in areas such as design, production and supply chain management. It is therefore wise to stay updated on new developments, even if you do not plan to adopt them (all).

To stay updated on new developments and applications in AI for the apparel industry, follow these online news sources:

- Online news platform Business of Fashion has a special technology section highlighting news about AI. Premium members get access to more in-depth studies about AI;

- Vogue Business frequently discusses AI’s impact on fashion, including its potential and environmental considerations;

- Sourcing Journal offers a technology section with the latest news on AI applications in the apparel industry;

- Online industry news platform Just Style also offers a technology section with news on AI;

- Premiere Vision offers a news section on their online platform with regular updates on AI’s role in apparel manufacturing and marketing. It highlights many new startup companies in the industry.

Google Alerts

If you never want to miss any news on AI in the apparel industry, create a Google alert. Go to Google Alerts and type in ‘AI’ + ‘Apparel’ or ‘AI’ + ‘Apparel manufacturing’. After providing your email address you will receive regular updates in your inbox.

Industry insights

Another great way to learn from industry insiders is to follow them on LinkedIn. Ben Hanson from online fashion technology magazine The Interline regularly posts interesting blog articles. Companies like Heuritech and Stylumia do the same. The LinkedIn group Innovation in Textiles has over 50,000 members and is a good source for news. It also lets you post articles or questions (after you have been granted access).

FT Journalistiek carried out this study in partnership with Giovanni Beatrice on behalf of CBI.

Please review our market information disclaimer.

Search

Enter search terms to find market research