6 tips on how to become more socially responsible in the grains, pulses and oilseeds sector

Improving your company’s social impact can make you more competitive in Europe, where social responsibility is a priority for consumers and governments. Companies choose responsible suppliers more and more often. That is why using recognised standards helps you show your commitment to sustainability.

Contents of this page

1. Show compliance with international social standards

Complying with international standards is the best way to become more socially responsible and profit from it. Public pressure and new laws push traders and processors to make sure supply chains are ethical. Buying from certified suppliers is an easy way to ensure social responsibility.

Internationally recognised standards set certain social responsibility practices to which you can compare your operations. Companies need different certifications depending on their type of operation and supply chain because social responsibility risks vary. Agricultural producers face challenges like insufficient personal protective equipment (PPE) or gender inequality. They can deal with these challenges by following the ETI Code of Conduct. Companies that buy from multiple small farmers benefit more from the Fairtrade Standard, which ensures fair trade practices and better conditions for small producers.

Buyers choose standards based on the risks they want to avoid, so knowing their preference helps you choose the right standard too.

Once a standard is being used, certification and third-party audits prove compliance. Certify your company to meet buyer expectations and stay competitive.

Choose a standard

The following standards are applicable to grain pulses and oilseeds. Each has its own unique areas of emphasis and approaches to achieving social responsibility. It is important to select the standard that aligns with your business needs and meets the requirements of your buyers.

SMETA

SMETA is a format for auditing social responsibility in a company. It is based on the Ethical Trading Initiative (ETI) Base Code and local laws, among others. SMETA addresses labour rights, health, safety, and environmental issues. The SMETA standard is widely recognised in the agri-food industry (including grains, pulses, and oilseeds). It is a Business-to-Business (B2B) standard, meaning that it is only visible to other companies, not to the end consumer.

After a SMETA audit, you will not receive a certificate. Instead, audit details are uploaded onto the Sedex online platform, so buyers can check your supply chain.

Figure 1: Fairtrade- and organic-certified wild rice from India in German supermarket Edeka

Source: GloballyCool, 2025

Fairtrade certification

Fairtrade is an internationally recognised certification that ensures ethical and sustainable production practices. It sets standards for fair wages, safe working conditions and environmental sustainability, particularly in developing countries. Products with the Fairtrade label meet strict criteria, so that farmers and workers get fair compensation. Certification is given by Fairtrade International and monitored through independent audits. This helps businesses to show their commitment to ethical sourcing and social responsibility.

The certification is shown by a logo on the packed product. This gives companies access to niche markets of fair, mostly specialty foods. Within this sector, Fairtrade certification is available for quinoa, rice, and snacks. One example of a certified producer is the Thai cooperative Green Net. Green Net has been able to supply their specialty rice to several key importers of specialty foods like Gepa and Eza. This has been possible thanks to their organic and Fairtrade certifications.

Video 1: Organic and Fairtrade rice from Thai company Green Net

Source: @TradeAid on Youtube

Note that there are other ‘fair’ certification programmes that are similar to Fairtrade, such as Fair for Life. An important difference between Fairtrade and Fair for Life is that Fair for Life recognises different standards, so it has a more flexible approach for complex supply chains. It also has a lower certification cost in general. On the other hand, Fairtrade is the most well-known ‘fair’ standard among consumers, which makes it very relevant for standalone products.

Standards related to ‘fair trading’ are more relevant for unusual products like quinoa, amaranth, fonio and sometimes rice sold as standalone products or as ingredients for unusual snacks. Grains, pulses and oilseeds with fair trade certifications are commonly also organic-certified. The majority of grains, pulses and oilseeds sold in the European market do not have a fairtrade certification.

B Corp

If sustainability is a top priority in your company, B Corp can be an interesting standard for you. This standard promotes social and environmental sustainability. It assesses the impact of the company on its workers, customers, community, and environment. It evaluates various aspects, including:

- governance;

- workers' rights;

- supply chain;

- community engagement; and,

- environmental practices.

B Corp certification is a standard that goes beyond the regular standards in showing sustainable performance and transparency. It is used by companies that are socially motivated and show a high commitment to sustainability – or by those that actively work on their social reputation.

With B Corp you can move ahead of other suppliers that are working on their social certifications. One of the relevant B Corp certified companies in Europe is Ecotone that owns some of the leading organic food brands such as Allos and El Granero.

Amfori BSCI

The Amfori Business Social Compliance Initiative (BSCI) is a compliance programme that provides a framework for improving social performance in supply chains. It is not a certification but a system for monitoring and improving working conditions. The report of a BSCI verification audit will be uploaded to the online Amfori BSCI platform so that the buyer can see it. This standard is mostly used by companies with complex supply chains in labour-intensive industries. But a few relevant players in Europe also use it, for example the importer Henry Lamotte in Germany and the supermarket chain Migros in Switzerland.

SA8000

The SA8000 is an international certification standard that ensures ethical labour practices, including fair wages, safe conditions, and workers’ rights mostly at big companies with many employees. Companies can get certified by independent bodies accredited by Social Accountability International (SAI). Like Amfori BSCI, SA8000 is used by big companies.

Communicate your certifications and other efforts on social responsibility

After you get your certification or verification, add the logo to your website, brochures, catalogues, trade show booth and any other materials or communications channel. Many European buyers require certifications, so you need to show them to attract potential buyers.

This not only applies to your certificate of social responsibility but also to all the efforts you do in supporting your community.

Examples from South America and Africa

The Bolivian cooperative Anapqui certified Fair Trade to benefit the smallholder producers and counter the excessive pressure of middleman in their community. This company is now a steady supplier of organic and Fairtrade quinoa to El Puente GMBH. El Puente is a key importer, of Fairtrade products in Germany. On Anapqui’s homepage, all their certificates are displayed. This way, they are the first thing visitors see when they enter the website. Right below, there is a box with information on fair trade practices and the impact they have on their community. This way, the company makes social responsibility a visible key aspect of its Unique Selling Point (USP).

Another example is the Ugandan company GADC. GADC exports sesame seeds among other products. On their website, they have a section on certifications. There, they include the SMETA and the Fair for Life logo. On top of that, their site is full of proof of their commitment to social responsibility and their impact on their community.

Video 2: Training program sponsored by GADC to farmers to improve productivity

Source: @GADC on Youtube

Tips:

- Mention the standards you comply with when sending the first e-mail to potential buyers. Adding the logo to your signature can also be helpful to call the buyer’s attention.

- Add a section about your social responsibility to your website. Include your certifications, standards, code of conduct and the projects for the community.

2. Tackle key safety risks in your company

A safe and healthy work environment is key for employees to perform at their best. Besides, European companies expect their suppliers to have adequate working conditions. So, taking care of the safety and occupational health of your workers will benefit them and help you comply with the buyer requirements.

Ensure basic safety measures in your facilities

Start with making sure that you have the basic safety measures in place. A common non-compliance in social audits of facilities in the grains, pulses, and oilseeds sector is the lack of basic safety measures. This can include:

- a first aid kit;

- firefighting tools (like a fire extinguisher);

- emergency exits;

- proper signalling of the emergency exit; and,

- an evacuation plan for emergencies.

Your local law might already require you to implement certain basic measures. If not, you can use the ILO’S Guidelines on occupational safety and health management systems as a guide. Some basic safety procedures for farms and handling facilities of grains, pulses, and oilseeds are:

- Designate specific points of exit in all relevant structures. Make sure that emergency exits are clearly marked and easily accessible to all workers. Inspect and maintain these exits on a regular basis to guarantee their functionality.

- Installing fire extinguishers at easily accessible locations and regularly inspecting them.

- Establishing clear evacuation routes and emergency assembly points.

- Installing danger signs to indicate overhead powerlines. This is especially important if tip trucks and augers operate nearby. Removing any obstacles that pose a trip or head knock hazard.

- Blocking off child access to ladders.

- Considering guards belts and conveyers.

- Installing lighting for safe use of storage at night.

Keep an eye on common health risks in the grain, pulses and oilseeds sector

There are several health and safety risks associated with growing and handling grains, pulses and oilseeds. Some risks come from a lack of protective equipment and training of the workers. Identify the hazards in your operations and make a plan to mitigate their negative effects.

Workers in the farming of grains, pulses, and oilseeds are at risk of several health conditions. Skin diseases are the most common occupational diseases. These can be caused by contact with contaminated water, bacteria, pesticides, insect stings and prickly plants, among others. Workers involved in the handling of grains, pulses and oilseeds have different risks. They are exposed to dust, spores, mycotoxins and endotoxins that can be harmful to the respiratory system. This can cause diseases like asthma and lung infections.

Provide proper PPE

You can reduce the risk of illness by providing proper Personal Protective Equipment (PPE). Provide respirators to workers handling the grains when the risk of dust exposure is high. For example: when loading or unloading the grains, during cleaning of the facilities, or in general, when the grains are being moved. Proper ventilation is also key to mitigating the risk posed by dust. Ear protection is also important to reducing the impact of loud machines on your workers.

PPE is also key when the workers are in contact with pesticides. Which PPE you should provide will depend on the instructions of each pesticide. Make sure you have a clear overview of which pesticides are being used and what type of PPE is required.

Also, raise awareness among your farmers about clothing to reduce contact with pesticides. They should wear long-sleeved shirts and long pants.

Address mechanical hazards

Several machines used in the handling and processing of grains, pulses and oilseeds can be dangerous to your workers. This is especially the case during maintenance activities. Conveyors and milling machines, for example, can cause severe finger or hand amputation. In fact, a common non-compliance of social audits in this sector is insufficient barriers covering the hazardous areas of critical machines. This poses a risk of injury to the workers.

Some preventive measures to reduce the risk of injuries through machines are:

- Install barriers around hazardous areas like grain mill cutters to prevent worker contact.

- Shut down or de-energise machines before maintenance to avoid accidentally starting them.

- Lock or tag equipment to prevent unauthorised or accidental operation during maintenance.

You should map the processes in your company, identify the hazards and improve the processes to minimise the risks.

Video 3: OSHA 5 Things to Know about Grain Safety

Source: @USDepartmentofLabor on Youtube

Train your workers

Most farm machinery injuries happen when workers have not had proper training. Safety measures only work if workers are well-trained and happy to follow to procedures. Train new workers from the start and give them regular training on safety procedures and machine use.

Also, make sure that your workers understand the health risks they are exposed to if they do not follow safety procedures and use the required PPE. This will help you create commitment among workers, which is very important for safety measures to be effective.

For more information, please check out this YouTube video: 'What is ISO 45001? Guide to Occupational Health and Safety (OHS) Standards' by ISO

Tips:

- Implement ISO 45001, a management system of occupational health and safety to reduce occupational injuries and disease.

- Consult the ILO´s Code of Practice of Health and Safety in Agriculture if you grow grain, pulses and oilseeds, and check the ILO´s Encyclopaedia for Health and Safety Hazards in Agricultural Grains and Oilseeds to identify common hazards and solutions.

- Check the ILO`s Encyclopaedia for Grain, Grain Milling and Grain-based Consumer Products if you handle or process grain, pulses and oilseeds.

3. Reduce gender inequalities in your chain

Promoting gender equality can help you start and keep business relations with European buyers. Start by identifying and addressing the potential issues inside your supply chain. Common issues in grains, pulses and oilseeds sector include: lack of access to credit, land, training and credit of women in comparison to men. Often women also receive much less income although they contribute to the farm activities like men.

Help empower the women in your supply chain by helping create cooperatives

Women make an important part of the agricultural force producing certain grains, pulses and oilseeds like Quinoa in Ecuador or Fonio in Mali. However, men often control the land and income, because they handle sales. Helping create cooperatives in which women are entitled to be part of the decision-making process of the collective can improve gender equality in your supply chain.

Give women voice and vote

In the Chimborazo region in Ecuador, for example, women are in charge of the Quinoa production. Nevertheless, men still had more power in the decision making, even though they were not even present at the farm. Also, many cooperatives allow only landowners to participate in decision-making, which excludes women. You can prevent this to happen by implementing other types of mechanisms that allow women to participate. For example, setting up a Women’s Committee within cooperatives can give women a voice in decision-making and support activities that improve their well-being.

Video 4: Gender and Decision-making: Quinoa Production among Indigenous Women in Rural Ecuador

Source: @WGD VT on Youtube

Include women in trainings

Companies can improve the quality, quantity and compliance of their suppliers’ produce by supporting cooperatives. They can do this with training on good agricultural practices, new machinery, and proper handling and storage. However, women often lack direct access to these opportunities. Making sure that all farmers, not just men, can use these initiatives strengthens the cooperative’s overall performance while giving women with the knowledge they need to work more efficiently.

In Ethiopia, for example, while men get access to training from experts from the government, NGOs, or the private sector, women get indirect and incomplete information through their husbands, neighbours and the community. One outcome of this is that women in Ethiopia often grow less productive and export-oriented varieties versus their male counterparts, like the case of the Haricot beans.

Tip:

- Ask the women in your supply chain about their current challenges and what solutions they see. Gender inequality looks different in each supply chain, depending on factors like culture, local rules and geography. Often our perception of their challenges will be biased, as it is very difficult to understand their experiences from the outside. A very important step to improve gender inequality is involving women in the conversation.

4. Improve your own operations and get to know your suppliers

It is important to know your supply chain well, so you can find out if there are any human rights violations or other non-compliance issues with the standards that your buyers require. Start looking inside your company, identifying and addressing the social issues that are in your hands. Then, get closer to your suppliers to start to understand and address their issues.

Focus on human rights first

As a direct supplier of a European company, you are expected to be free of grave non-compliances against Human Rights and the health and safety of your direct workers. Make sure that your operations fully comply with the local law in the first place. Then evaluate them against the standard you would like to implement or the code of conduct of your buyer.

For example, a common issue in grains, pulses and oilseeds factories is the lack of proper timekeeping. This can lead to legal violations and non-compliance with buyer codes of conduct and international standards. Installing a punch clock can easily resolve this. But companies must also make sure that workers receive proper payment and rest based on recorded hours. There are also digital tracking systems that will help you automate time-tracking. This gives you not only transparency in working hours but also opportunities to improve productivity.

Work directly with the farmers in your chain

Many social issues in the grains, pulses and oilseeds supply chain happen during production. Exporters often buy through intermediaries. This makes it harder to keep an eye on origin, quality, and farmers’ working conditions.

Establish direct contact

If you find yourself in this situation, it will be very challenging to implement meaningful social responsibility measures and ensure quality for exporting to Europe. Establishing direct contact with the producers is crucial. Include your current partners or intermediaries. They know the farmers better and might help you identify some risks, as well as share the information with them.

Start evaluating the working conditions and processes according to your own code of conduct, an internationally recognised standard that you have determined for yourself, or the requirements that your buyers have on this topic.

Create a strategy based on the identified risks

There is no universal solution for enhancing social responsibility in your supply chain. Once you have identified the issues that need to be improved, you will have to create an action plan to address them. Put in place measures to follow local law and address grave Human Rights violations like Child and Forced Labour practices.

Documenting your efforts is key to improving social impact within your supply chain. Solving social issues takes time, and buyers understand this. Keep records of supply chain mapping and actions you have taken. Even if the issues are still there, showing progress can be enough, depending on their severity.

Tips:

- Check the criteria of some standards of your interest in Standardsmap. Identify which criteria must be fulfilled immediately and start working on them as soon as possible. Do you buy from several smallholder farmers? Then check the standards for Fair Trade. Do you have your own farms? Compare the SMETA audit, Amfori BSCI and SA8000.

- Check The Sustainable Rice Platform, which has a set of standards to guarantee sustainability through the whole supply chain of rice, if you are a rice exporter. This set of standards is internationally recognized among rice buyers in Europe.

5. Comply with international human right standards

European companies must follow regulations on human rights in their supply chains. Exporters who show they really care about human rights are more likely to attract buyers, especially large companies.

There are some risk factors for human right violations across the agricultural chains that also apply for grain pulses and oilseeds. For example, products grown in family farms present a risk of child labour and very low compensation leading to poverty. Also, day labourers, seasonal or migrant workers have a higher risk of suffering from working in unsafe conditions.

If your supply chain also has this type of risks factors, it might as well be at risk of violating these and other Human Rights. To tackle that risk, you should map your supply chain and address the issues.

A study conducted by ETI Sweden found out that there is a high risk of child and forced labour in the production of sesame seeds in Sudan. The risk factors in this case are:

- smallholder farmers are the main producers, which receive very low compensation from middlemen; and,

- predominance of immigrant seasonal workers.

After this study, the recommendation to buyers sourcing sesame seeds from Sudan was to map and investigate their specific supply chain and to investigate the risk of sourcing from other origins.

Nevertheless, supply chains vary in countries, regions and products, so it´s important that you assess your own supply chain and identify your own risks. The OECD (Organisation for Economic Co-operation and Development) has a guideline for responsible agricultural supply chains. It can help you set your own due diligence plan to identify and address human rights violations.

European Union (EU) – Corporate Sustainability Due Diligence Directive (CSDDD)

The Corporate Sustainability Due Diligence Directive (CSDDD) says that large companies must address environmental and human rights impacts in their operations and supply chains. It has been effective since 2024, and EU countries must implement it by 2026, with application in phases starting in 2027.

High-risk sectors like agriculture and food will need to apply stricter rules due to risks such as child labour, forced labour, pollution and deforestation. Companies must ensure ethical sourcing, fair worker treatment and corrective action plans. For example, if a company buys grains from farms where workers are not paid fairly or do not have protective equipment, they must take steps to improve conditions or change suppliers.

Businesses in these high-risk sectors may need more audits, certifications and transparency measures. The law applies to EU companies with 1,000+ employees and a turnover of €450 million or more, and also affects non-EU suppliers. The EU is reviewing potential scope and timeline changes, so stakeholders should stay informed.

Due diligence laws at a national level

Certain European countries have regulations that hold domestic companies responsible for Human Rights violations happening in their supply chains, even if those violations happen in other countries or involve their suppliers. To avoid potential penalties, companies subject to these regulations may prefer to engage in trade with companies that have established systems to monitor and address the risk of Human Rights violations.

France, Germany, the United Kingdom, Norway, and the Netherlands have already regulations in place that require due diligence on Human Rights at different levels. Also, Austria, Finland, Belgium and Luxemburg are in the process of creating their own regulations.

EU members must incorporate the CSDDD into their national law. That is why other EU members are expected to follow. Germany and France will also have to adapt their laws to the CSDDD.

Germany – Supply Chain Act

The LkSG (Lieferkettensorgfaltspflichtengesetz), the Act on Corporate Due Diligence Obligations in Supply Chains requires companies to carry out Human Rights and environmental due diligence in their supply chains. This includes their own business operations, the activities of contractual partners, and the actions of other indirect suppliers.

This Act focuses on different human rights issues related to typical supply chain risks, such as prohibition of child labour and protection against slavery and forced labour. The Act currently applies to companies in Germany with a minimum of 1,000 employees.

SMEs looking to supply to German companies should show that they respect human rights in their operations. Doing this properly will increase their chances of being chosen by German buyers. They can show this by:

- Having a social responsibility certification (see Tip no. 1);

- Keeping clear records that show how they prevent child labour and forced labour, and ensure workplace safety for their employees; and,

- Having a Code of Conduct that follows national labour laws and follows international labour standards (ILO).

Now that the CSDDD has been approved, the LkSG must be changed to be in line with it on aspects such as the company scope and the due diligence aspects covered.

France – Loi de Vigilance

The Duty of Vigilance Act (Loi de Vigilance) requires companies to establish, implement, and publicly disclose their own vigilance plan based on the United Nations' human rights due diligence procedure outlined in the Principles on Business and Human Rights (UNGPs). A vigilance plan maps and identifies risks throughout the company's value chain, including its own operations and its suppliers.

The LdV will have to be changed as well, to match the CSDDD.

Other countries with due diligence laws in processing

Three other countries with due diligence law initiatives are the Netherlands, the United Kingdom and Norway.

- In the Netherlands, the Child Labour Due Diligence Law requires companies to investigate whether their goods or services involve child labour, create a plan to prevent child labour in their supply chains if identified, and report their efforts. The implementation of this law has been delayed due to ongoing discussions about integrating it into the CSDDD. A final decision has still not been taken.

- The Dutch government also passed the Responsible Business Conduct Act (WIVO) about human and labour rights, and environmental due diligence. This regulation makes the CSDDD part of Dutch law. The implementation process of this law is ongoing and changes can still take place.

- The Modern Slavery Act in the United Kingdom requires that all businesses operating in the UK with an annual turnover of £36 million or more must create a statement on slavery and human trafficking for each financial year. This statement should explain the actions taken by the organisation during the year to prevent modern slavery in both their supply chains and their own operations.

- The Norwegian transparency act requires companies to set up and use a due diligence process that is in line with OECD Guidelines. The act applies to Norwegian-based companies as well as foreign companies that sell products or services in Norway and meet at least two of the following three criteria: an annual turnover of 70 million NOK (more than €6 million), a balance of 35 million NOK (more than €3 million) or more, or having 50 full-time employees or equivalent annual man-hours.

Take care of your part in the supply chain

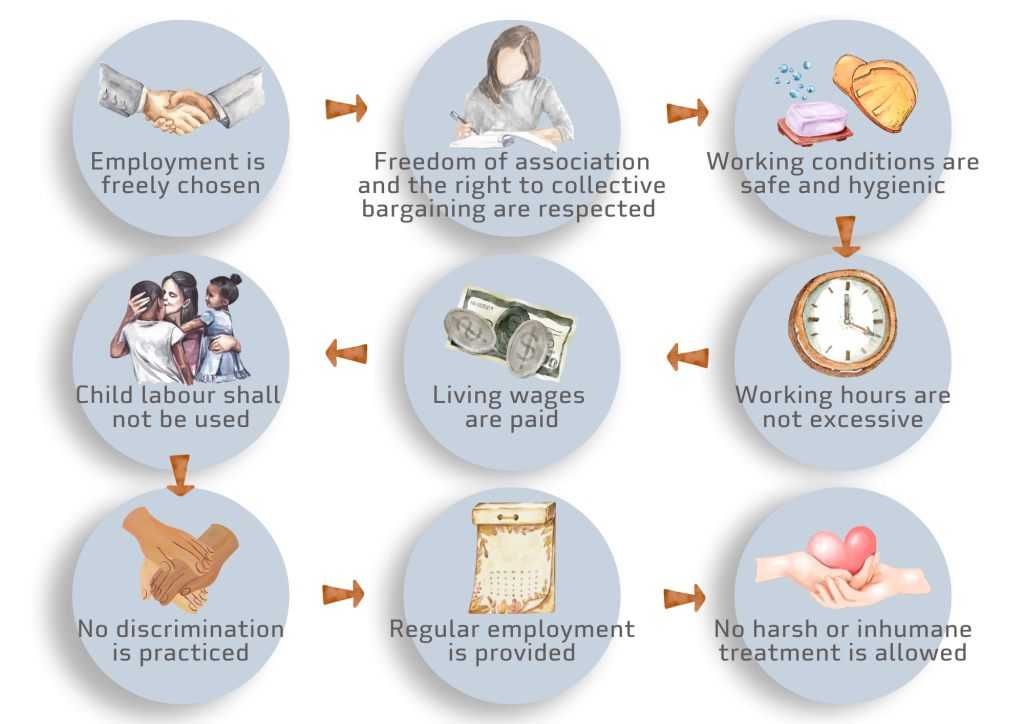

Start assessing your compliance with basic Human Rights principles against the ETI Base Code. ETI is a global reference standard to conduct social audits. These are the main principles of the ETI Base Code, which build the base for Codes of Conduct and other social standards:

Figure 2: Nine principles of the ETI Base Code

Source: ETI Base Code / GloballyCool, 2023

Video 5: Introduction to Ethical Trade from ETI

Source: @EthicalTrade on YouTube

Sustainability requires continuous improvement

Taking care of your social responsibility involves engaging in a continuous process of mapping your operations and those of your suppliers, identifying, preventing, mitigating, and managing risks. For example, to avoid child labour in your operations, it is not enough to check if all your employees are adults. You should adapt your hiring process so you can guarantee that no children will be hired in the future. For example, by asking future employees to provide a copy of a document that can prove their age. This will not only allow you to comply but also provide your company with documentation to prove your compliance.

Tips:

- Check the OECD Due Diligence Guidance for Responsible Business Conduct and the UN Guiding Principles on Business and Human Rights framework, which the CSDDD is based on.

- Consult the guideline on conducting risk analysis as required by the German Supply Chain Due Diligence Act to get an idea of how to conduct a risk analysis of your supply chain.

6. Let your buyer know that you care

Social responsibility is definitely an issue for grains, pulses and oilseeds buyers in Europe. Demonstrating your compliance with this aspect can be a crucial factor to win the interest of new clients. Let them know that you understand what is expected from you in the supply chain and that you can be a trusted partner.

Create a code of conduct reflecting their own

European companies often adopt a code of conduct to address Human Rights protection and ethical practices in their supply chains. This code typically includes key elements such as Human Rights (as seen in the ETI Base Code), compliance with local laws, and the prohibition of unethical practices.

Create your own Code based on the ETI Base Code or on your buyer’s code. Show compliance through your Code and evidence of your actions. The table below shows the nine principles of the ETI Base Code and the type of information you should include in your own Code to show your commitment to social responsibility.

Table 1: Principles of the ETI Base Code and how SMEs can tailor their own to match the requirements

| Principle | Proof of compliance for Small and Medium-sized Enterprises (SMEs) in developing countries |

|---|---|

| Employment is freely chosen | If your local law forbids forced labour and related practices, mention it and say which law it is. State that you do not lodge your workers' papers and that the notice period in your company complies with local law. |

| Freedom of association | If there is a national law that supports the freedom of association, mention the law. Mention any labour unions that your workers are affiliated with and highlight any programs or initiatives you engage in with them. |

| Working conditions are safe and hygienic | If there is local legislation on working conditions, mention it. If you comply with any recognised standard that regulates working conditions like ISO 45001, include it. |

| Child labour shall not be used | Include any measures you have in place to actively monitor and prevent child labour within your company and throughout your supply chain. Highlight any initiatives or actions implemented by your company to support and benefit children in your local community or in the community of your suppliers. |

| Living wages are paid | State that you comply with your country’s legislation on minimum wage. Include any extra benefits your company offers. For an internationally recognized reference, you can check the living wage of your country according to the Global Living Wage Coalition. If the salaries of your company are equal of higher than the minimum calculated by this organisation, mention it. |

| Working hours are no excessive | Mention compliance with the local law on this aspect and say which law it is. If your workers have better conditions than the minimum defined by the law in terms of working hours, holidays, or similar, include it. |

| No discrimination is practiced | Show your commitment to combat all forms of discrimination within your company. If there is a significant risk of discrimination in your country, acknowledge it and highlight the measures you are taking to mitigate it. For instance, you can highlight the presence of a women's committee or any initiatives aimed at promoting the employment of individuals from religious or ethnic minority groups. |

| Regular employment is provided | State that you comply with the local law in terms of formal employment. If you have any measure in place to reduce contracting seasonal workers in favour of having permanent employees, also mention it. |

| No harsh or inhumane treatment is allowed. | If there is a local law forbidding harassment, physical, verbal or sexual abuse, name it and state that you comply with it. |

Source: ETI Base Code / GloballyCool, 2023

Tips:

- Keep in mind that the ETI Base Code might be stricter on some aspects than your local law. For example, the code defines a maximum of 48 hours a week. If your local legislation allows for more, you should align with the code.

- Always include compliance with local law. This is a very important requirement in European buyers’ Codes of Conduct.

- Check out the Supplier Code of Conduct of Bunzl, a British multinational company that buys grains, pulses and oilseeds around the world. Find out what they expect from their suppliers when it comes to Corporate Responsibility.

GloballyCool carried out this study on behalf of CBI.

Please review our market information disclaimer.

Search

Enter search terms to find market research